The tilting disc check valve, as check valve is opened when flow goes through one direction and closes at backflow

The tilting disc check valve, as check valve is opened when flow goes through one direction and closes at backflow

Thanks to the fast closure of this versatile valve, pump protection is one of its main applications.

It is used for gases and liquids, bus it is not recommended when there are solids in suspension. The head drop is

relatively low.

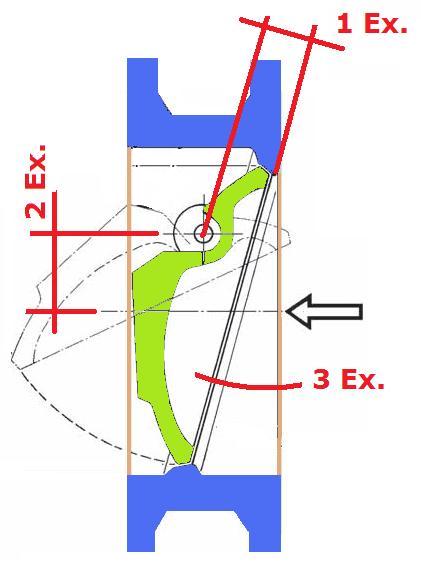

Tilting disc valves are designed with three eccentricities:

• First eccentricity: it is the offset between the shaft and the seat plane. This eccentricity removes any interference of the seat with the shaft and therefore

the seat has an integral and continuous construction both in the body and disc, and potential leakage can be avoided.

• Second eccentricity: it is the offset between the shaft and the disc diameter.

This eccentricity works when reverse comes or normal flow pressure is so low than it can't make enough

force to hold the closing torque caused by the weight of the disc.

• Third eccentricity: it is the angle of tilting of the seat plane with the normal plane of the pipe. This tilting reduce

the stroke of the disc, therefore it could close faster at backflow.

Furthermore of geometry and weight of the disc, in same cases other elements can optimize the closing sequence.

Springs can be used in order to increase the speed of the disc closure before reverse flow starts. In the other side, when reverse flow is a reality but the valve still not close at all

a slow closure can avoid slam over the valve. There are several oleo-hydraulic damper systems.

In order to tighten the valve, springs and also counterweights assemble at the end of the shaft can be used.

Minimum work pressure provided by manufacturers should be take into account when selecting valves for low pressure

applications, if not disc can be buffeted and in constant motion between the seat and partially open. This leads

to seat damage and shaft wear. This effect is more important in swing check valves.