Diaphragm valves

are used on shut-off and throttling service for liquids, slurries and vacuum/gas.

Diaphragm valves

are used on shut-off and throttling service for liquids, slurries and vacuum/gas.

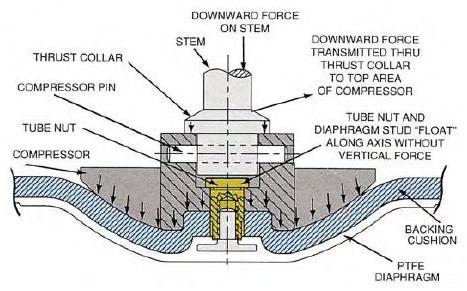

The seal is achieved by a flexible membrane, usually elastomer, and possibly reinforced with a metal part. The membrane is tensed

by the effect of a stem/compressor with lineal movement until contact is made against the seal of the body.

The operating parts of the diaphragm valve are isolated from the flow. This makes this valve suitable for viscous flows and also hazardous, abrasive and corrosive flows as

its sealing system avoids any contamination towards or from the environment.

Diaphragm valves are available in a wide variety of metals, solid plastics, plastic, rubber and glass linings. They are well

suited to the handling of multiple chemical applications both clear fluids as well as slurries.

The diaphragm valve has an extended use for applications at low pressures and slurry fluid where most other kinds of valves corrode or become obstructed.

It is a quick opening valve.

There are two types of diaphragm valves:

• Weir: The Weir Diaphragm valve can be used for either off/on and throttling services

• Straightway: named also Straight-Thru is only used for on/off services.

Example Diaphragm Closure System

General Features and ranges for Diaphragm valves

|

Diameter ranges:

From 0.5" to 14".

Connection to the pipe:

Butt-weld, Clamp, Flange, Screwed, Socket and Spigot Weld.

Diaphragm material:

Buna N (NBR), Butyl (CIIR), Ethylene Propylene Rubber (EPDM), Hypalon® (CSM), Natural Rubber (NR),

Neoprene (CR), PTFE and Viton® (FKM).

Temperature range:

From -10ºc (-14ºF) up to +170ºC (+350ºF) - (Depending on material).

Pressure range:

From 13.8 bar (200psi) - (Depending on material).

Fluid Velocity limitation:

15-20 ft/sec for clean fluids and 8-10 ft/sec for slurries.

Typical applications:

Chemical, Fossil Power Plants, Pharmaceutical, Mining, Nuclear Power Plants, Water treatments...

|