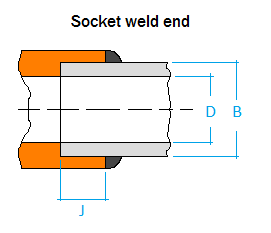

The socket welding ends are prepared by boring in each end of the valve a socket with an inside diameter slightly

larger than the pipe outside diameter. The pipe slips into the socket where it butts against a shoulder and then

joins to the valve with a fillet weld.

The socket welding ends are prepared by boring in each end of the valve a socket with an inside diameter slightly

larger than the pipe outside diameter. The pipe slips into the socket where it butts against a shoulder and then

joins to the valve with a fillet weld.

Socket welding ends in a given size are dimensionally the same regardless of pipe schedule. They are usually

furnished in sizes through 2-inch.

Socket Welding up to Ansi B16.11

Nominal Pipe Size

NPS

[inches] | Nominal Diameter

DN

[mm] | Socket Bore Diameter

B [mm] | Min. Depth of

the socket

J [mm] |

| min. | max. |

| 1/8 | 10 | 10.8 | 11.2 | 9.5 |

| 1/4 | 8 | 14.2 | 14.6 | 9.5 |

| 3/8 | 10 | 17.6 | 18.0 | 9.5 |

| 1/2 | 15 | 21.8 | 22.2 | 9.6 |

| 3/4 | 20 | 27.2 | 27.6 | 12.5 |

| 1 | 25 | 33.9 | 34.3 | 12.5 |

| 1 1/4 | 32 | 42.7 | 43.1 | 12.5 |

| 1 1/2 | 40 | 48.8 | 49.2 | 12.7 |

| 2 | 50 | 61.2 | 61.7 | 16.0 |

| 2 1/2 | 65 | 73.9 | 74.4 | 16.0 |

| 3 | 80 | 89.8 | 90.3 | 16.0 |

| 4 | 100 | 115.2 | 115.7 | 19.0 |

Standards for Socket-Welding connections

B16.11 - 2009 Forged Fittings, Socket-Welding and Threaded

This Standard covers ratings, dimensions, tolerances, marking and material requirements for socket-welding and threaded forged fittings.

These fittings are designated as Class 2000, 3000, and 6000 for threaded end fittings and Class 3000, 6000, and 9000 for socket-weld end fittings.