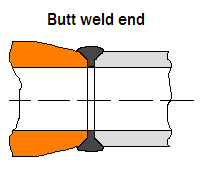

The buttwelding ends are prepared by beveling each end of the valve to match a similar bevel on the pipe. The

two ends are then butted to the pipeline and joined with a full penetration weld.

The buttwelding ends are prepared by beveling each end of the valve to match a similar bevel on the pipe. The

two ends are then butted to the pipeline and joined with a full penetration weld.

This type of joint is used on all

valve styles and the end preparation must be different for each schedule of pipe. These are generally furnished

for control valves in sizes 2-1/2-inch and larger.

Care must be exercised when welding valve bodies in the

pipeline to prevent excessive heat transmitted to valve trim parts. Trims with low-temperature composition materials

must be removed before welding.