|

Normas aplicables a las válvulas de globo

IEC 60534-3-1 Ed. 1.0 b:2000

Industrial-process control valves - Part 3-1: Dimensions - Face-to-face dimensions for flanged, two-way, globe-type,

straight pattern and centre-to-face dimensions for flanged, two-way, globe-type, angle pattern control valves

Especifica en las válvulas de control la distancia entre cara (FTF) y cetro a cara (CTF) según el diámetro, presión de la brida,

dos vias, tipo globo, paso recto y angular.

IEC 60534-3-2 Ed. 2.0 b:2001

Industrial-process control valves - Part 3-2: Dimensions - Face-to-face dimensions for rotary control valves except butterfly valves

Gives the overall lengths of following types: segmental ball, eccentric rotary plug, and barstock globe; wafer butterfly valves are excluded.

IEC 60534-3-3 Ed. 1.0 b:1998

Industrial-process control valves - Part 3-3: Dimensions End-to-end dimensions for buttweld, two-way, globe-type, straight pattern control valves

Specifies end-to-end dimensions for given nominal sizes and pressure ratings of buttweld, two-way, global-type, straigth pattern control valves for

nominal sizes DN 15 through DN 450. Aids users in their piping design by providing normalized dimensions of buttweld end control valves.

IEC 60534-8-3 Ed. 2.0 b:2000

Industrial-process control valves - Part 8-3: Noise considerations - Control valve aerodynamic noise prediction method

Establishes a theoretical method to predict the external sound-pressure level generated in a control valve by the flow of compressible

fluids. Applies to the following single-stage valves: globe (single and double seated), butterfly, angle, rotary plug (eccentric, spherical), ball,

and valves with cage trims.

ISO 12149:1999

Bolted bonnet steel globe valves for general-purpose applications

ISO 15761:2002

Steel gate, globe and check valves for sizes DN 100 and smaller, for the petroleum and natural gas industries

ISO 15761 specifies the requirements for a series of compact steel gate, globe and check valves for petroleum and natural gas industry applications. It is

applicable to valves of nominal sizes (DN) 8, 10, 15, 20, 25, 32, 40, 50, 65, 80 and 100, to corresponding nominal sizes, to nominal pipe sizes (NPS) of a

quarter, three eighths, half, three quarters, one, one and a quarter, one and a half, two, two and a half, three and four, and to pressure designation classes

150, 300, 600, 800 and 1500. It includes provisions for a wide range of valve characteristics and is applicable to valve end flanges in accordance with ASME B16.5

and valve body ends having tapered pipe threads to ISO 7-1 or ASME B1.20.1.

ISO 21787:2006

Industrial valves -- Globe valves of thermoplastics materials

ISO/CD 15761

Steel gate, globe and check valves for sizes DN 100 and smaller, for the petroleum and natural gas industries

ASTM F1370-92(2005)

Standard Specification for Pressure-Reducing Valves for Water Systems, Shipboard

1.1 This specification covers self-contained, globe style, pressure-reducing valves for use in water systems of shipboard installations. These valves are

limited to discharge pressure settings of 200 psig (1379 kPa) and below.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

The following precautionary caveat pertains only to the tests portion, Section , of this specification:This standard does not purport to address all

of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limitations prior to use.

ASTM F1565-00(2006)

Standard Specification for Pressure-Reducing Valves for Steam Service

1.1 This specification covers self-contained, internally operated, globe style, pressure-reducing valves for use in steam service. In these valves, the downstream

pressure feedback is sensed by a spring-loaded diaphragm to position a pilot valve-the pilot valve uses the inlet steam pressure to position the main valve plug via

an operating piston.

ASTM F1794-97(2004)

Standard Specification for Hand-Operated, Globe-Style Valves for Gas (Except Oxygen Gas), and Hydraulic Systems

1.1 This specification covers the design, construction, testing, and operating requirements for hand operated, quick-change cartridge trim, in-line body and angle-body,

globe style valves for use in gas (except oxygen gas), and hydraulic systems. These valves may be used for on-off, and/or throttling applications.

1.2 The values stated in this specification in inch-pounds units are to be regarded as the standard. The SI equivalent shown in parenthesis are provided for information only.

ASTM F1985-99(2005)

Standard Specification for Pneumatic-Operated, Globe-Style, Control Valves

1.1 This specification covers the design, construction, testing, and operating requirements for pneumatic-operated, globe-style, control valves complete with actuators for various

fluid systems (steam, gas, and liquid applications). The control valves with actuators may be procured under this specification complete with all associated pneumatic instrumentation

necessary for the valve to function in the system application; however, complete and detailed requirements for air instrumentation are beyond the scope of this specification and thus

are not included here. This specification is not intended to cover quarter-turn or multi-turn stem valves.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

ASTM F885-84(2006)

Standard Specification for Envelope Dimensions for Bronze Globe Valves NPS ¼ to 2

1.1 This specification provides standard dimensions for small bronze globe valves (NPS 1/4 to 2) installed in shipboard piping systems.

1.2 This specification covers valves of a nominal pipe size from NPS 1/4 to 2 with threaded and brazed end connections. The valves are in accordance with MSS-SP80, Class 200.

BSR/ASTM Z7973Z-200x

Specification for Steel Globe Valves (DRAFT STANDARD)

75.08.01

Face-to-Face Dimensions for Integral Flanged Globe-Style Control Valve Bodies (Classes 125, 150, 250, 300, and 600) Formerly ISA 75.03

ANSI/ISA 75.08.03-2001

Face-to-Face Dimensions for Socket Weld-End and Screwed-End Globe-Style Control Valves (Classes 150, 300, 600, 900, 1500, and 2500) (Formerly ANSI/ISA 75.12-1993)

This standard applies to socket weld-end globe-style control valves, sizes 1/2 in (15mm) through 4 in (100mm), and screwed-end globe-style control vales, sizes 1/2

in (15 mm) through 2 1/2 in (65mm)

ANSI/ISA 75.08.04-2001

Face-to-Face Dimensions for Buttweld-End Globe-Style Control Valves (Class 4500) (Formerly ANSI/ISA 75.14-1993)

This standard applies to buttweld-end globe-style control valves, sizes 1/2 inch (15mm) through 8 inches (200 mm), having top and cage guiding

ANSI/ISA 75.08.07-2001

Face-to-Face Dimensions for Separable Flanged Globe-Style Control Valves (ANSI Classes 150, 300, and 600) (Formerly ISA 75.20-1991)

This standard applies to separable flanged globe-style control valves, sizes 1 inch through 4 inches

ANSI/ISA S75.15-1994

Face-to-Face Dimensions for Buttweld-End Globe-Style Control Valves (ANSI Classes 150, 300, 600, 900, 1500 and 2500)

ANSI/ISA S75.16-1994

Face-to-Face Dimensions for Flanged Globe-Style Control Valve Bodies (ANSI Classes 900, 1500 and 2500)

ANSI/ISA S75.22-1999

Face-to-Centering Dimensions for Flanged Globe-Style Angle Control Valve Bodies

Applies to raised-face, flanged, globe-style, angle control valves, 1 inch through 8 inches.

ISA S75.03-1992

Face-to-Face Dimensions for Integral Flanged Globe-Style Control Valve Bodies (ANSI Classes 125, 150, 250, 300, and 600)

MSS SP-117-2006

Bellows Seals for Globe and Gate Valves

1.1 This Standard Practice covers requirements for design, materials, fabrication, installation, qualification, examination, testing,

and shipment of metal bellows and/or bellows assemblies to be installed in manual and automated on-off globe and gate valves.

1.2 This Standard Practice is applicable to metal bellows used in conjunction with steel globe and gate valves which otherwise satisfy

the requirements of standards such as API600/ISO10434, API602/ISO 15761, ASME B16.34 and API603. Such standards are referred to herein

as the "parent" valve specifications.

1.3 This Standard Practice does not apply to non-metallic bellows or bellows made of low melting point materials such as brass,

phosphor-bronze, or similar materials.

1.4 Except where specifically noted in the text of this Standard Practice, the requirements here are not intended to supersede or replace those

requirements of the parent valve standard. This standard specifies additional requirements for those valves utilizing bellows seals.

1.5 It is the responsibility of the bellows valve manufacturer to ensure compliance with this Standard Practice.

MSS SP-118-2007

Compact Steel Globe & Check Valves - Flanged, Flangeless, Threaded & Welding Ends (Chemical & Petroleum Refinery Service)

This Standard Practice covers flanged end, flangeless end, threaded end, socket-welding end, and butt-welding end compact steel globe and check

valves. The term "compact" is used to identify the valves covered by this Standard Practice as reduced seat port(2) valves. Valve sizes correspond to nominal pipe sizes

listed in ASME B36.10M and B36.19M. Flanged, flangeless, and butt weld end valves are limited to NPS 4 and smaller; threaded and socket welding

end valves are limited to NPS 2 1/2 and smaller. Valves covered under this Standard Practice shall meet the requirements of ASME B16.34, "Standard Class".

MSS SP-120-2006 (2006)

Flexible Graphite Packing System for Rising Stem Steel Valves - Design Requirements

1. This Standard Practice establishes material and dimensional requirements for valve packing, packing chamber, packing gland, packing washer,

bonnet, and stem as they relate to the total packing assembly.

2. This Standard Practice applies to standard, special, and limited Class 150 through Class 4500 (including intermediate classes) ASME B16.34 type steel gate, globe,

and angle valves designed with rotating/ rising and non-rotating/rising stems.

3. This Standard Practice applies to valves in which a flexible graphite packing assembly is used as the primary stem-sealing system.

4. This Standard Practice does not apply to valves that include a lantern ring as part of its packing system nor to bonnetless valves with split glands.

MSS SP-121-2006

Qualification Testing Methods for Stem Packing for Rising Stem Steel Valves

1. This Standard Practice provides procedures and guidelines for testing and evaluation of valve stem packing materials and material combinations. This

testing provides qualification by verifying the adequacy of specific packing material combinations for service within defined limits of size, pressure,

temperature, and cyclic duty. Such specific combinations generally represent products of individual manufacturers, although generic qualification of raw

materials may be demonstrable in certain cases.

2. It is intended that this Standard Practice apply to qualification of stem packings for Class 150 through 4500 ASME B16.34 or equivalent steel or special

alloy valves (including intermediate classes and Standard, Special, and Limited Class ratings) with rotating/rising and non-rotating/rising stems, as traditionally

used in globe and gate valves. Other valve stem types (e.g. quarter-turn) may involve additional considerations not within the scope of this Standard Practice.

- The requirements herein apply to qualification of traditional compression packings. Rod seal elements

such as "O" rings, "V" rings, and similar proprietary seals are not within the scope.

- Stem packings may be prequalified by experience or by test programs conducted prior to publication of this Standard Practice

if a qualification report is prepared based on documented evidence.

3. This Standard Practice is intended to provide experimental qualification of packing materials and materials combinations for service

with water, steam, and other common liquids, vapors, and gases. Some of the procedures identified in detail use water and steam as test fluids,

but air or nitrogen may also be used with appropriate modifications in testing and data acquisition methods.

MSS SP-42-2004

Class 150 Corrosion Resistant Gate, Globe, Angle and Check Valves with Flanged and Butt Weld Ends

This Standard Practice is intended to provide a vehicle for the standardization, to the extent indicated, of those features of

the valves covered herin. The valves are made from corrosion resistant alloys whose properties are uniquely suited to the service into which they are

placed. Chemical process and cryogenic fluid service constitute two such applications.

MSS SP-80-2003

Bronze Gate, Globe, Angle and Check Valves

This MSS Standard Practice establishes requirements for bronze gate, globe, angle, and check valves in Classes 125 (PN 20), 150, 200,

300 (PN 50) and 350 for threaded and solder ends and Classes 150 (PN 20) and 300 (PN 50) for flanged ends. Pressures in this Standard Practice

are gauge pressure in pounds per square inch (kPa). Hereafter the pressure will appear as psi (kPa).

SP-117

Bellows Seals for Globe and Gate Valves

SP-118

Compact Steel Globe & Check Valves Flanged, Flangeless, Threaded, & Welding Ends (Chemical & Petroleum Refinery Service)

SP-42

Class 150 Corrosion Resistant Gate, Globe, Angle and Check Valves with Flanged and Butt Weld Ends

SP-80

Bronze Gate, Globe, Angle and Check Valves

SP-85

Gray Iron Globe & Angle Valves, Flanged and Threaded Ends

AS 1628-1999

Water supply - Metallic gate, globe and non-return valves

Specifies requirements for metallic gate, globe and non-return valves of nominal sizes DN 8 to DN 100 for use in hot and cold water applications

where the operating temperature does not exceed 99°C.

AS 1628-1999/Amdt 1-2001

Water supply - Metallic gate, globe and non-return valves

A-A-50541 NOT 2

Valves, Tank Float, Angle and Globe Pattern

MIL-V-1187C NOT 1

valve, angle, and valves, globe bronze, threaded 300 pound wsp rating (S/S BY MSS-SP80)

MIL-V-1202C NOT 1

Valves angle & valves globe bronze (S/S BY MSS-SP80)

MIL-V-16271F NOT 1

Valves, tank float, angle and globe pattern (S/S BY A-A-50541)

MIL-V-18434B NOT 1

Valve, gate globe, & angle, steel (USE ANSI B16.34)

MIL-V-2187A NOT 1

Valve, angle and globe, manually operated, naval shipboard, magazine sprinkling and test fittings,

MIL-V-22052D

Valve, stop and stop check, globe, angle, and y pattern, cast or forged carbon or alloy steel, outside screw and yoke (sizes 2-1/2 inches and larger)

MIL-V-22094D NOT 1

Valve, globe, stop check, angle and y, flanged bonnet, manually operated (sizes 2 inches and below) (see notice for replacement information)

MIL-V-24109A

Valve, globe, angle, quick change cartridge trim, high pressure (h-p.) hydraulic and pneumatic (sizes 1/8- 1 1/4 inches)

MIL-V-24578

Valve, globe, pressure instrument, stem test connection, union end

MIL-V-24578B

Valve, globe, pressure instrument, stem test connection, union end

QPL-17501-13 NOT 1

Valves, globe, hydraulically operated, piston and diaphragm type, magazine and hangar deck sprinkling

QPL-22052-27

Valve, stop and stop check, globe, angle, and y pattern, cast or forged carbon or alloy steel, outside screw and yoke (sizes 2-1/2 inches and larger)

QPL-24109-10

Valves, globe, angle, quick change cartridge trim, high pressure (h.p.) hydraulic and pneumatic (sizes 1/8 - 1-1/4 inches)

WW-V-51F NOT 1

valve, angle, check, & globe, bronze (125, 150 & 200 pound, threaded end, flange ends, solder ends, & brazed end, for land use) (s/s by MSS-SP80)

EN 13709

Industrial valves - Steel globe and globe stop and check valves

EN 13789

Industrial valves - Cast iron globe valves

EN ISO 15761

Steel gate, globe and check valves for sizes DN 100 and smaller, for the petroleum and natural gas industries

EN 60534-3-1

Industrial-Process Control Valves Part 3-1: Dimensions - Face-To-Face Dimensions for Flanged, Two-Way, Globe-Type, Straight Pattern

and Centre-To-Face Dimensions for Flanged, Two-Way, Globe-Type, Angle Pattern Control Valves

EN 60534-3-3

Industrial-Process Control Valves Part 3-3: Dimensions - End-to-End Dimensions for Buttweld, Two-Way, Globe-Type, Straight Pattern Control Valves

DIN 3356-1:1982

Globe valves; General data

DIN 3502

Stopvalves for domestic water supply - Two-way valves - Oblique bonnet type PN 10; Y-type valve; Technical rule of the DVGW

The document specifies in connection with DIN EN 1213 dimensions, requirements and tests for oblique bonnet globe valves for nominal sizes

DN 15 to DN 80 and up to PN 10 for domestic water supply.

DIN 3512

Stopvalves for domestic water supply - Two-way valves - Vertical bonnet type PN 10; Straight pattern globe valve; Technical rule of the DVGW

The document specifies in connection to DIN EN 1213 dimensions, requirements and tests for straight pattern globe valves

for nominal sizes DN 10 to DN 80 and up to PN 10 for domestic water supply.

DIN 3844

Valves for heating installations; copper alloy globe valves PN 16 with screwed sockets; dimensions, materials

DIN EN 12567:2000

Industrial valves - Isolating valves for LNG - Specification for suitability and appropriate verification tests; English version of DIN EN 12567

The document defines the general performance requirements of isolating valves (globe valves, plug valves, ball valves, butterfly valves) used in the production,

storage, transmission (by pipelines, rail, road or sea) of Liquefied Natural Gas (LNG).

DIN EN 13709:2003

Industrial valves - Steel globe and globe stop and check valves

This European Standard specifies the requirements for steel globe and globe stop and check valves

which are wrought, cast or fabricated in straight, angle or oblique pattern with end connections flanged,

butt welding, socket welding or threaded. This standard is applicable to steel globe and globe stop and check

valves mainly used for industrial and general purpose applications. However they can be used for other applications

provided the requirements of the relevant performance standards are met.

DIN EN 13774:2003

Valves for gas distribution systems with maximum operating pressures less than or equal to 16 bar - Performance

This EN deals with isolating valves used for gas distribution systems with maximum operating pressure 16 bar, and which operate with fuel gases of the first

and second family, according to EN 437. It applies to valves DN 25 and larger. The types of isolating valves to be considered are: plug and

ball valves, gate valves, globe valves and butterfly valves.

DIN EN 13789:2003

Industrial valves - Cast iron globe valves

This European Standard specifies the requirements for cast iron globe valves in straight, angle

or oblique pattern with flanged or threaded end connections. This standard applies to cast iron

globe valves mainly used for industrial and general purpose applications. However they can be used

for other applications provided the requirements of the relevant performance standards are met.

DIN EN 60534-3-1

Industrial-process control valves - Part 3-1: Dimensions; Face-to-face dimensions for flanged, two-way, globe-type,

straight pattern and centre-to-face dimensions for flanged, two-way, globe-type, angle pattern control

valves (IEC 60534-3-1:2000); German version EN 60534-3-1:2000 + Corrigendum 2000

The document specifies face-to-face and centre-to-face dimensions for given nominal sizes and pressure ratings of

flanged, to-way, globe-type, straight pattern and angle pattern control valves. The nominal sizes included are DN 15 through DN 400 for straight pattern

control valves and DN 25 through DN 400 for angle pattern control valves.

DIN EN 60534-3-3

Industrial-process control valves - Part 3-3: Dimensions - end-to-end dimensions for buttweld, two-way, globe-type, straight

pattern control valves (IEC 60534-3-3:1998); German version EN 60534-3-3:1998

The document specifies end-to-end dimensions for given nominal sizes and pressure rating of buttweld, two-way, globe-type control valves for nominal sizes DN 25 through DN 450.

DIN EN ISO 15761

Steel gate, glob and check valves for sizes DN 100 and smaller, for the petroleum and natural gas industries (ISO 15761:2002); German version EN ISO 15761:2002 (German and English text)

This International Standard specifies the requirements for a series of compact steel gate, globe and check valves for petroleum and natural gas industry applications. It is applicable to

valves of nominal sizes DN 8, 10, 15, 20, 25, 32, 40, 50, 65, 80 and 100, corresponding to different (nominal pipe sizes) NPS

and to pressure designations of classes 150, 300, 600, 800 and 1500. This International Standard is applicable to valve end flanges

in accordance with ASME B16.5 and valve body ends having tapered pipe threads to ISO 7-1 or ASME B1.20.1. It is applicable to extended

body construction in sizes 15 smaller DN smaller 50 and pressure designations of class 800 and 1500, and to bellows and bellows assembly construction as may be

adaptable to gate or globe valves. It covers bellows stem seal-type testing requirements.

DIN EN ISO 21787

Industrial valves - Globe valves of thermoplastics materials (ISO 21787:2006); German version EN ISO 21787:2006

This Standard specifies requirements and tests for globe valves of thermoplastics materials for isolating and control service.

This Standard is applicable to hand or power operated valves to be installed in industrial pipe systems.

JIS B 2005-3-1:2005

Industrial-process control valves -- Part 3-1: Dimensions -- Face-to-face dimensions for flanged, two-way, globe-type, straight pattern and centre-to-face

dimensions for flanged, two-way, globe-type, angle pattern control valves

JIS B 2005-3-3:2005

Industrial-process control valves -- Part 3-3: Dimensions -- End-to-end dimensions for buttweld, two-way, globe-type, straight pattern control valves

JIS B 2011:2003/AMENDMENT 1:2004

Bronze gate, globe, angle, and check valves (Amendment 1)

B 2301

Bronze Gate, Globe, Angle and Check Valves

V 7311

Shipbuilding- Bronze 5K Globe Valves

V 7313

Shipbuilding - Bronze 16K Globe Valves

V 7331

Marine Malleable Iron 5kgf/cm2 Globe Valves (E)

V 7333

Marine Malleable Iron 16kgf/cm2 Globe Valves (E)

V 7339

Marine Forged Steel 40kgf/cm2 Globe Valves

V 7346

Marine Forged Steel Globe Valves for Compressed Air

V 7356

Marine Bronze 5K Globe Valves (Union Bonnet Type) Marine Bronze 5K Globe Valves (Union Bonnet Type)

V 7361

Bronze Gate, Globe, Angle and Check Valves

Marine Bronze 5kgf/cm2 Screw-Down Check Globe Valves (E)

V 7398

Bronze Gate, Globe, Angle and Check Valves

Marine Bronze 20kgf/cm2 Globe Valves (E)

V 7401

Bronze Gate, Globe, Angle and Check Valves

Marine Cast Iron 3kgf/cm2 Globe Valves

V 7403

Marine Bronze 3kgf/cm2 Globe Valves

V 7413

Marine Hull Bronze Globe Valves

V 7419

Marine Bronze 16kgf/cm2 Screw-Down Check Globe Valves

V 7421

Bronze Gate, Globe, Angle and Check Valves

Marine Bronze 5kgf/cm2 Screw-Down Check Globe Valves (Union Bonnet Type)

V 7423

Marine Bronze 16kgf/cm2 Screw-Down Check Globe Valves (Union Bonnet Type)

V 7425

Marine Bronze 5kgf/cm2 Lift Check Globe Valves (Union Bonnet Type)

V 7427

Marine Bronze 16kgf/cm2 Lift Check Globe Valves (Union Bonnet Type)

V 7431

Marine Forged Steel 20kgf/cm2 Globe Valves

ONORM EN 13709:2003

Industrial valves - Steel globe and globe stop and check valves

Fr Absperrventile und absperrbare Rckschlagventile aus Stahl, die geschmiedet, gegossen oder geschweit

sind, sind Anforderungen festgelegt. Die Festlegungen gelten, in Abhngigkeit von der Anschlussform, fr den

Nennweitenbereich von DN 8 bis DN 400 und fr den Nenndruckbereich von PN 10 bis PN 100 sowie fr Class 150 bis

Class 800. Behandelt sind Durchgangs-, Eck- oder Schrgausfhrung sowie die Anschluformen Flansch-, Anschwei-,

Schweimuffen- oder Gewindeenden. Neben den Angaben ber Werkstoffe sind auch die Bettigungsarten, die wesentlichen

Funktionsmerkmale sowie die erforderlichen Prfungen beschrieben. Weiters sind Hinweise auf die Konformittserklrung, die

Kennzeichnung sowie Angaben fr die Vorbereitung, fr die Lagerung und den Versand sowie Bestellangaben enthalten.

ONORM EN 13789:2003

Industrial valves - Cast iron globe valves

Festgelegt sind die Anforderungen an Ventile aus Gusseisen, welche in Durchgangsform, Eck- oder Schrgsitzform, mit Flansch- oder Gewindeanschlssen hergestellt werden.

Die Festlegungen gelten fr einen Nennweitenbereich von DN 10 bis DN 400 und fr Gewindeanschlsse 1/2 bis 2 sowie in einem Nenndruckbereich von PN 6 bis PN 16 fr Flansch-

und Gewindeanschlsse und PN 25 nur fr Flanschanschlsse. Fr Gehuse und Oberteil sind die zulssigen Werkstoffe aufgelistet sowie Einschrnkungen bei der Druck-Temperatur-Zuordnung angegeben.

Detaillierte Anforderungen an die Baulngen und Gehuseenden sowie fr die Bettigung sind gegeben. Hinweise auf die

erforderlichen Prfungen, die Konformittserklrung sowie auf die Bezeichnung und Kennzeichnung sind ebenso vorhanden

wie Angaben fr die Bestellung oder eine Gegenberstellung fr die Gleichwertigkeit von Werkstoffen

nach EN- oder ISO-Normen. Weiters sind die jeweiligen Abschnitte angefhrt, welche die grundlegende Anforderungen oder andere Vorgaben von EU-Richtlinien betreffen.

ONORM EN ISO 15761:2003

Steel gate, globe and check valves for sizes DN 100 and smaller, for the petroleum and natural gas industries (ISO 15761:2002)

Festgelegt sind die Anforderungen an Schieber, Ventile und Rckflussverhinderer fr den Bereich der Erdl- und Erdgasindustrie. Die Festlegungen gelten fr einen

Nennweitenbereich von DN 8 bis DN 100, bzw. fr NPS 1/4 bis

NPS 4 sowie fr den Druckstufenbereich von PN 20 bis PN 260 bzw. Class 150 bis Class 1500, in den jeweils fr die Armaturenart angegebenen Grenzen. Hinweise auf die

Ermittlung des Druck-Temperatur-Verhltnisses sowie auf die Durchflussermittlung sind gegeben. Die Ermittlung der erforderlichen Wanddicken ist beschrieben. Eine Auswahl

an mglichen Werkstoffen ist enthalten. Detaillierte Angaben fr die Prfung und berprfung sind vorhanden. Die Bezeichnung der einzelnen Armaturenteile

sowie Hinweise fr die Bestellung sind angegeben.

ONORM EN ISO 21787:2006

Industrial valves - Globe valves of thermoplastics materials (ISO 21787:2006)

Festgelegt sind die Anforderungen und Prfungen fr Ventile zum Absperren und Regeln aus thermoplastischen Werkstoffen.

Die Festlegungen gelten fr hand- und kraftbettigte Armaturen, die in industrielle Rohrleitungen eingebaut werden, und umfassen den Nennweitenbereich von DN 15 bis DN 150

sowie den Druckstufenbereich von PN 6 bis PN 16 sowie Class 150. Die Druck-Temperatur-Zuordnung der behandelten Werkstoffe gilt fr Temperaturen

zwischen -40 C und +120 C und fr eine Lebensdauer von 25 Jahren. Neben den technischen Anforderungen, wie Klassifizierung und Konstruktionsanforderungen

sind die Werkstoffe und die erforderlichen Prfungen beschrieben. Die erforderlichen Angaben fr die Kennzeichnung sind enthalten. Hinweise fr die

Vorbereitung der Lagerung und den Versand sind angegeben.

NZS/BS 5152

Cast Iron Globe and Globe Stop and Check Valves for General Purposes BS 5152: 1974

GB/T 12233-1989

General purpose industrial valves-Casting iron globe valves and lift check valves (TEXT OF DOCUMENT IS IN CHINESE)

GB/T 12235-1989

General purpose industrial valves-Flanged steel globe valves and lift check valves (TEXT OF DOCUMENT IS IN CHINESE)

NBR15055

Bronze gate, globe, angle and check valves TEXT OF DOCUMENT IS IN PORTUGUESE

NBR15083

Globe and angle valves, flanged anmd threaded ends TEXT OF DOCUMENT IS IN PORTUGUESE

Establede los requisitos para válvulas de globo y angular en hierro fundido.

NBR15119

Steel globe, glob stop and check valves (flanged and butt-welding ends) for the petroleum, petrochemical and allied industries TEXT OF DOCUMENT IS IN PORTUGUESE

Estabelece os requisitos para vlvulas-globo e vlvulas-globo de retenao, padrao reto, angular ou Y (oglquo).

ANSI/API 621-2001

Reconditioning of Metallic Gate, Globe, and Check Valves

Guia para recondicionar bridas y finales por 'soldadura a tope' en válvulas de fundición y forjadas.

ANSI/AWWA C530-2007

Pilot Operated Control Valves

This standard establishes minimum requirements for pilot operated control valves of globe, angle and wye body styles with various

end connections in sizes from 1 ½ inch (37.5 mm) through to 60 inch (1500 mm), in diameter, with water having a pH range from 6

to 9 and a temperature range from 40ºF to 125ºF (4.4 to 52ºC). The standard covers piston and diaphragm type valves

suitable for a maximum steady state fluid working pressure of 300 psig - (2.070 kPa), and a maximum steady-state

differential pressure of 300 psig (2.070 kPa), and a maximum line velocity of 15 ft/s (4.6 m/s.

|

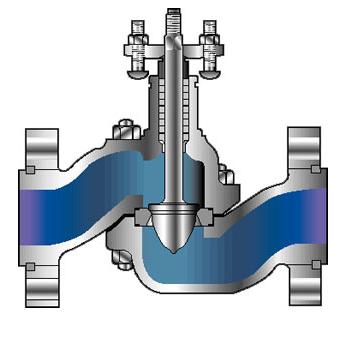

Las válvulas de globo son llamadas así por la forma esférica de su cuerpo. Si bien actualmente

algunos diseños ya no son tan esféricos, conservan el nombre por el tipo de mecanismo.

Las válvulas de globo son llamadas así por la forma esférica de su cuerpo. Si bien actualmente

algunos diseños ya no son tan esféricos, conservan el nombre por el tipo de mecanismo.